At Spectre, we uphold the mantra, "not just to be good, but to be the best." And for us, it means that we will continuously keep developing, exploring, optimizing, and innovating. Acknowledging the perpetual evolution of ourselves, our partners, and the world, we strive to support our partners with "the new and the next."

But what does innovation in Spectre really look like?

Innovation for us surpasses the mere introduction of new ideas and products. It involves optimizing and evolving existing products, materials, and especially technologies—a commitment integral to sustainability. With over 75 years in the industry, we have continually evolved and refined our practices.

Some of those practices are found in our technical capabilities. This is a focal point where we truly excel as a preferred development and manufacturing partner for high-end functional garments. And to continue delivering ‘high-end,’ we optimize and automate already existing processes.

While the benefits of automation sound appealing, we understand you’re likely wondering, “What’s in it for me?”

Here are some of our personal preferred outputs:

Efficiency – Automating some of our processes means performing certain repetitive tasks faster. It also means increased production speed, fulfilling large orders more quickly and overall efficiency.

Quality – Systems can detect defects, irregularities, or deviations from specifications, ensuring that only the high-quality garments reach the market.

Responsible practice – Reducing material waste, optimizing energy use, and enabling customization fosters eco-friendly practices that align with some of our sustainability goals and are minimizing environmental impact.

Production speed – Automated systems significantly accelerate garment manufacturing processes, ensuring quicker response to market trends, shorter lead times, and efficient small-batch production. This agility enhances competitiveness and reduces time-to-market.

Maximize material utilization – Our automated processes are optimized to minimize material waste. Our cutting systems, for example, efficiently lay out patterns on fabric to maximize usage and reduce the amount of unused material.

Consistency – Our machines can cut, sew, and assemble pieces with accuracy, reducing the likelihood of errors and variations in product quality.

We strive to offer the absolute best product, providing various technical capabilities, from embroidery and lamination to seam sealing and diverse technical cutting. We even got machines, developed only at Spectre, that don't appear anywhere else than at our productions. But to make it a little more specific (and nerdy) here are some examples of how we stand out as a specialized manufacturer of functional garments.

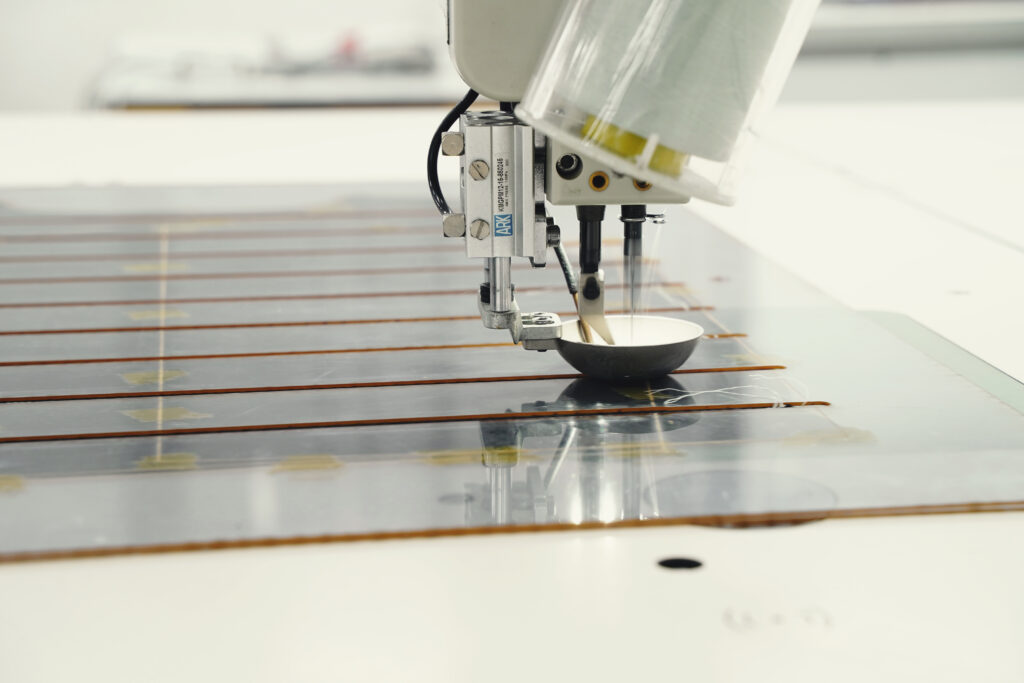

Our Kissing flaps solution on for example jackets is one of the technologies that we recently automated.

The parts are placed in the center of the front, and therefore a precise detailed configuration is required. It has a seam allowance of just 1-2 mm, and even with a slight change in the accuracy of the seam, the shape of the component changes after reverse.

In the initial solution, the seamstress had to place the fabric in a template, then sew according to the template, and finally cut off excess fabric with scissors.

In the final automated solution, we auto sew and it provides precise detailed configuration. All details have a perfect equal seam allowance. The sewing process itself is also faster than manually sewing shapes like this. Finally, the cutting block with the laser cutter is much faster than cutting every detail separately, which also means that the seamstress’ work is relieved.

Another recently automated process is the sewing of our zip garages.

In the initial solution the seamstress must have good skills, and the sewing operation itself must be very precise. But despite that each sewing line performs this operation differently.

In the semi-automated sewing process, it is very easy to learn and perform the sewing operation, which means that it is also suitable for new seamstresses. All parts are of the exact same quality. And the semi-automation makes it easier to sew the zipper into the garment.

It’s no secret that we are deeply committed to developing wind- and waterproof garments and we have worked with GORE-TEX Windstopper garments for more than 20 years. When considering weather protection, the key factors are the fabric quality for wind and waterproofing. We prioritize providing insulation without added bulk and moisture-wicking features without extra layers. Our products are available in either 3-layer or 2 ½-layer options, with fabrics typically featuring a membrane for effective wind protection and water repellency or resistance.

In 2023 we implemented the GORE-TEX technology with the new ePE membrane from Gore, which has three core benefits: Durable waterproof, reliable breathable and totally windproof. And along with 3D drawings, it is one of our latest initiatives in our innovation field.

The above are just some examples on how we continuously develop, innovate, and automate our processes in technical capabilities.

Specialized manufacturer of functional garments.

We develop and produce functional garments together with international outdoor- and sports brands.